Machine precision parts efficiently and precisely

New UGIMA® 4598 stainless steel improves productivity and quality

Whether minute technical components in clocks, delicate axes for dental drills or small parts in mobile phones: UGIMA® 4598 is the optimum steel grade in every application requiring excellent part quality at smallest dimensions at an affordable price. Characteristic of this new stainless steel from Ugitech, a subsidiary of the SCHMOLZ + BICKENBACH Group, is its excellent machinability. When compared to the conventional stainless steel grades used, manufacturers of precision parts note an increase of productivity of up to 40 percent during rough machining and an up to 80 percent improvement during drilling when compared to a standard 1.4404. The new special steel is also corrosion-resistant and capable of meeting a wide range of requirements. Ugitech achieves this optimum balance in the steel's properties by means of excellent technical expertise in steel production – a competence possessed by Ugitech as one of the few special steel producers in Europe.

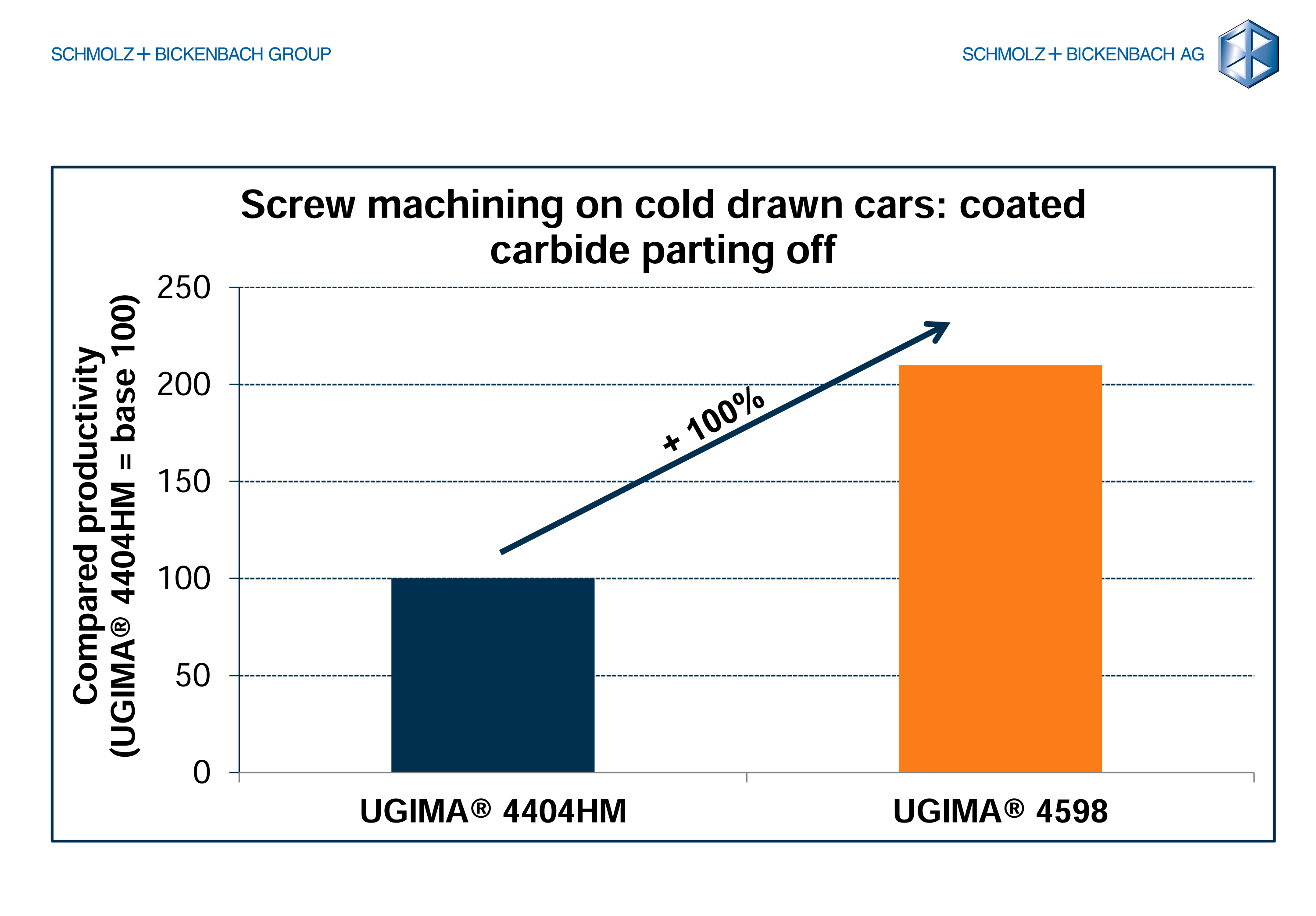

Optimized for machining – that is the decisive attribute of the UGIMA® stainless steel solutions from Ugitech: The new UGIMA® 4598 is based on the chemical analysis of stainless steel UGIMA® 4404. Ugitech improved machinability by means of specific additions such as copper and sulfur as well as specific precipitation that result in superior chip breakability. As a rule, machining tools are thereby subject to less stress which reduces abrasive wear and lowers production costs. In developing the new stainless steel the special steel manufacturer is responding to increasing demand from the electronics and clock and watch-making industry, dental technology and from manufacturers of fine screw and connector technology for an affordable and time-saving stainless steel grade. "Demand for the stainless steel grade 1.4598 has risen over the past few years, particularly in the mobile communications sector," emphasizes Marc Marticou, Business Development Manager at Ugitech. "With our special manufacturing processes and vast competence, we have succeeded in clearly exceeding the conventional market material design in terms of its machinability." Optimized for machining, UGIMA® 4598 is ideally suited to machining on state-of-the-art CNC machines that reach cutting speeds of 14,000 rpm and more. Stress tests during screw manufacture of cold-drawn bars with a diameter of 15 mm confirm: compared to the standard steel grade 1.4404, productivity improves up to 100 % by using carbide tools for steel tapping – without an increase in tool wear. Users improve productivity by 80 percent when drilling steel bars with a diameter of six millimeters.

The UGIMA® 4598 stainless steel is available from the SCHMOLZ + BICKENBACH Group Sales & Services network worldwide as steel bar and wire in diameters of six to 25 millimeters.

Photo 1: Fine screws made of UGIMA® 4598, Source: Ugitech

Photo 2: Productivity Comparison, Source: Ugitech

About Ugitech S.A.

Ugitech is one of the leading manufacturers of stainless steel long products worldwide. The company's main products include billets, bar stock, wire rod, drawn wire that the company produces in its own steel mill and in its rolling mills and wire-drawing plants. The stainless steels are known for their excellent mechanical properties. They are used to manufacture a wide range of parts, such as e.g. valves, turbine components, welding wire or surgical instruments. With over 100 years of experience in steel production and ongoing metallurgical research, the company guarantees optimum steel solutions for demanding applications for its customers in the automotive, construction, process and aviation industries and medical technology.

About SCHMOLZ + BICKENBACH

Today, the SCHMOLZ + BICKENBACH Group is one of the world’s leading providers of customised solutions in the specialty steel long products business. A global name in tool steel and stainless long steel, the Group is one of two largest companies in Europe for alloy and high-alloy engineering steel. With around 9.000 employees at its own production and distribution companies in 35 countries across five continents, the Company supports and supplies customers wherever they operate. Besides the comprehensive Production and Sales & Services portfolio, customers benefit from the Company’s technological expertise, consistent high quality worldwide and in-depth knowledge of local markets.

Corporate Contact

Frédérique Tissot • Ugitech S. A.

Phone: +33 (0)47989-3012 • Fax: +33 (0)47989-3737

E-Mail: frederique.tissot(at)ugitech.com • Internet: www.ugitech.com

Stefanie Steiner • SCHMOLZ + BICKENBACH Group

Phone: +41 (0)41 209-5042 • Fax: +41 (0)41 209-5043

E-Mail: s.steiner(at)schmolz-bickenbach.com

Internet: www.schmolz-bickenbach.com

External media contact

Hanna Hagedorn • additiv pr GmbH & Co.KG

Public relations for logistics, steel, industrial commodities and IT

Herzog-Adolf-Straße 3 • D-56410 Montabaur

Phone: +49 (0)2602 95099-15 • Fax: +49 (0)2602 95099-17

E-Mail: hh(at)additiv-pr.de • Internet: www.additiv-pr.de